|

The

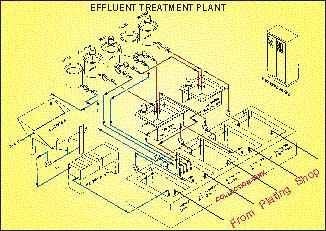

manual plant for ETP generally consist of :-

Collection

Tanks :

The

tanks are mostly in pits, with Acid/Alkali

resistant paint or bricks lining, to store

rinse water in segregation of v Alkali

v Cyanide v Acids v hexavalent Chrome v others individually or in permissible

combination. Each tank is fitted with discharge

pump, control panel with level control alarms,

iron grating and fittings.

Dosing

Tanks: 5

PP Dosing Tanks with fittings of suitable capacity for storage and

dosing of reagents for treatment of effluents, for gravitational

discharge, provide easy access to the tank during working &

refilling of reagents.

Treatment

Tanks:

Two Nos. PP tanks of suitable volume fitted

with motorized stirrer and compressed air

supply to ensure a total mix up of reagents,

suitable pumps. The treatment is controlled

and monitored by digital ORP and pH meters.

Settlement

Tank:

One No. Sludge settlement tank PP/PVC lined in M.S. of suitable

volume, with conical bottom, discharge valves for water and sludge,

level indicator. Such treated water is either reused or discharged

into sewer lines.

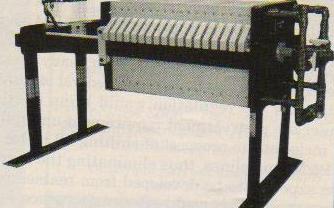

Filter

Press:

Filter Press generally manually operated of suitable capacity, with

screw pump for dewatering up to 75 %, having PP filter plates of 355 x

355 mm. to 1200 x 1200 mm. in different filtering area and discharge

ranges.

Chemicals:

Conventional chemicals for Hexavalent Chrome Reduction and Cyanide

Oxidisation are available. Some of the known neutralizing agents are

Lime, Soda Ash, Caustic, Calcium Chloride, Potash Alum, Sodium Meta

bi-sulphate and Magnesium Hydroxide. Selection should be based upon

cost, usage requirement, handling and sludge production.

Analysis

Kit:

A

ready kit of glasswares and chemical reagents

are available for easy estimation of total

cyanide and total hexavalent chromium present

in the effluent and also to test the treated

water to the discharge standards.

KCPL is the reliable source not only for complete

ETP Equipments but from pH Adjust or Neutralisation

Systems and Batch Treatment Systems, large

or small, to flow through Continuous Sedimentation

Systems, Clarifiers, Oil Skimmers, Evaporators,

Filter Presses and Sludge Management equipment.

Also, Rinse Water-Recycling Systems.

KCPLs Effluent Treatment

Systems are fully integrated, stand-alone,

equipment systems that effectively treat

process wastewater streams to comply with

local standards for discharge. Whether the

requirements are to correct pH, to precipitate

heavy metals, to remove oils from process

tanks or waste streams, to filter sediments

and particulate, to evaporate with zero

discharge, or to close-loop and recycle,

we have the exact treatment technology to

meet the need.

Komals Cyanide Destruct

Systems safely breakdown harmful cyanides

from waste streams.

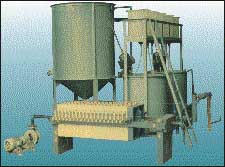

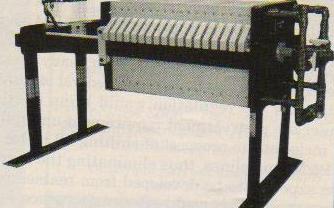

FILTER

PRESSES

The Filter

Press has been the focus product of Komal

for many years. We have built a solid reputation

for supplying quality Filter Presses, Clarifiers,

Sludge Dryers, Complete Waste Treatment

Systems, Filter Cloths and Filter Plates.

Our Filter Presses have been used in number

of industries from plating and metal finishing.

Komal Filter Presses feature heavy duty

steel construction with polypro gasketed

plates. These filter presses can be manufactured

with manual or with a hydraulic cylinder,

high pressure closing. Komals Filter Presses

are always expandable for larger future

capacity by adding longer sidebars and additional

plates.

The filter press is

most often used in the dewatering of metal

finishing sludges. It is simple to operate,

and produces a dry, easily disposable filter

cake. Sludge from the thickener or directly

from the bottom of the clarifier, is usually

pumped via an air diaphragm pump to the

filter press. The PP filter media retains

the solid while the liquid portion or filtrate

flows through the media and discharges.

Filtrate usually returns to the collection/equalization

tank for retreatment. After a certain length

of time (2-4hours) the chambers of the press

are completely full and a filter cake of

25-35% solids has formed. The hydraulic

pressure that had been holding the plates

is now released and the filter cake is discharged

Standard

Filter Press Features

Air Driven Hydraulic Closing Pump with

Pressure Gauge on Automatic Units

Heavy Duty Hydraulic Cylinder for opening

and closing of Press.

Polypro Gasketed Recessed Plates for leak

free operation

Air Blown Manifold Piping for Air Drying

Filter Cakes.

Air Line Filter, Oiler, Regulator, and

Guage on Automatic Units.

Optional Features

Sludge Dump Carts for Sludge collection

and dumping

Cat-Walk Platform with raised legs for

disposal into Drums or our Sludge Dryer.

Automatic Plate shifter for ease of cleaning.

Distance piece for future expansion.

Leg mounted Control Panel.

Diaphragm pump for solids feed to the

Filter Press.

Filter

Press applications

Dewatering industrial Sludge

Reclaiming precious Metals

Product Filtration

Dewatering Hazardous Wastes

Process Waste Waters as per PCB approved

Treatment Systems.

CLARIFIERS

The inclined parallel plate design, manufactured

by KCPL are used as part of a ETP system

for efficient solid settlings, are constructed

of carbon steel with coal tar epoxy lining

on the inside, and epoxy coating on the

exterior. The internal plate pack is set

at 60% for optimum settling and is constructed

of a epoxy coated steel shell or with FRP

plastic plates.

The Komal Clarifiers

use the time proven concept of inclined

plate clarification. This type of clarifier

uses gravity in conjunction with the projected

settling area of the 60 degree angle parallel

plates to settle solids from the pre-treated

liquid flow. This treated liquid flows first

to the flocculation tank where polymer is

added to promote floc growth, then up through

the plate pack(s) while the solids settle

out to the bottom sludge cones. The clean

water flows out through our special laundering

troughs to plant discharge or for polishing

for water reuse. The solids are intermittently

taken from the bottom cone to a filter press

for further dewatering.

|