|

ADDITIONAL

INFORMATION

KCPL

is a leading manufacturer of innovative

state-of-the-art pollution control products.

Our design and engineering specialist are

ready to work for you Ė helping you to meet

the challenges. With years of engineering

and sales experience we are continually

looking for new and better ways to deal

with the increasingly complex Air and Environment

Control problems.

Komalís Ventilation

systems are designed on the basis of 2 premise.

The control of atmospheric contamination

is possible through general or dilution,

and local exhaust ventilation (LEV) to provide

a safe, healthy environment for employees,

and to protect them against potentially

toxic and irritating airborne contaminants

generated in the work place. Our ventilation

systems limit worker exposure to within

the maximum permissible exposure limits

(PEL) mandated by your local Air pollution

authorities, or to within the guideline

threshold limit values (TLV). Air discharge

limitations have become stricter in the

last few years due to increasing air concern

about the effects of air pollution.

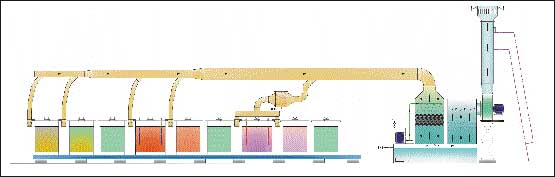

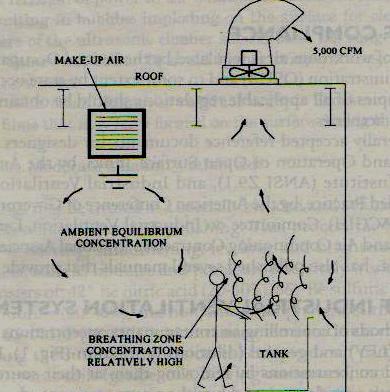

The former

type (i.e. general) (see Fig 1) functions

by causing sufficient air to pass through

the room or shop to dilute the contaminant

or contaminated air entering the space under

consideration from outside. Thus windows

fans, roof fans, central ventilating systems,

etc., accomplish general ventilation.

Fig

1:- General dilution ventilation - room

behaves as a mixing chamber.

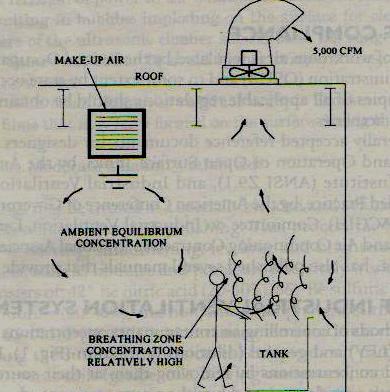

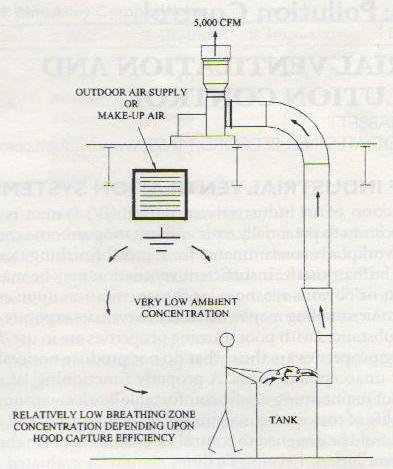

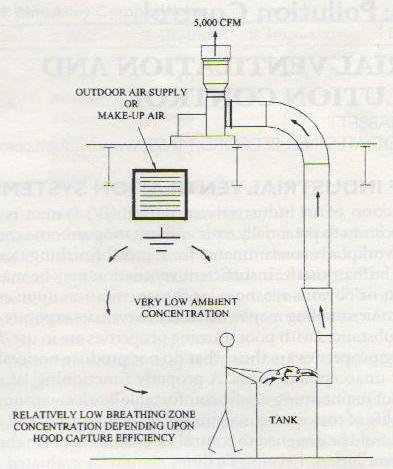

Komalís

Local exhaust ventilation (LEV) systems

(see Fig 2), on the other hand, functions

by capturing the contaminant or grossly

contaminated air as close to its source

or point of release as possible and conveying

it to the outside either directly or after

passing through air pollution control devices

where necessary. Local exhaust is a must

if the amount of contaminant escaping is

considerable, to prevent the creation of

a health hazard. Slot-type exhaust hoods

at tanks, and canopy type hoods above tanks

are examples of local exhaust hoods. If

the concentration of the contaminant in

the air exhausted is much greater than in

the general room air, the ventilation is

local exhaust. Many plating and metal-finishing

shops have a number of different open surface

tank processes that require exhaust ventilation.

Air contaminants from open surface tanks

vary in type, intensity and toxicity, depending

upon the operation. These are significant

factors when determining ventilation and

air pollution control requirements for a

facility.

Fig

2:- Local exhaust ventilation - localized

(sourse) capture results in lower air contaminant

concentration in the breathing zone and

general work area.

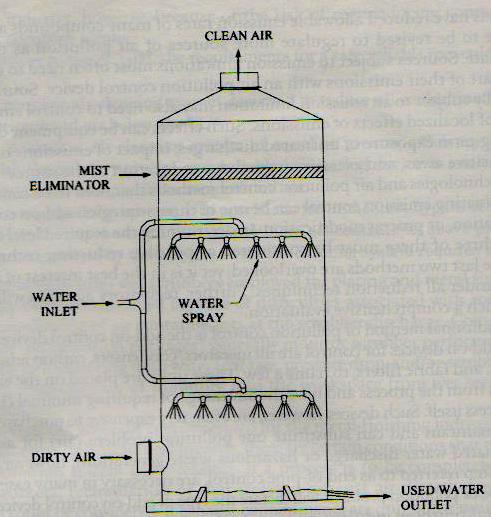

Komalís

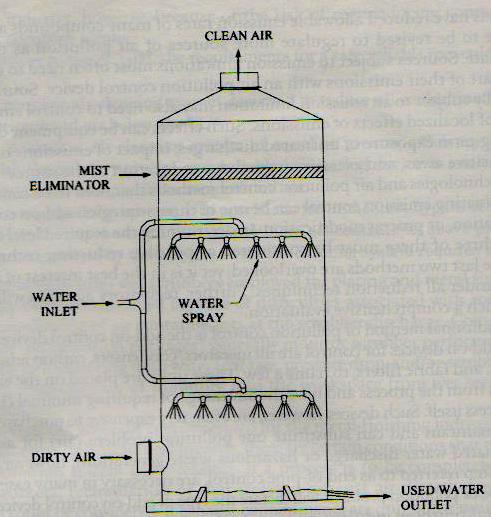

Wet collectors (also called as Wet scrubbers)

are the most suitable pollution control

devices for removing acid/alkali pollutants.

In our lower end simple scrubbers, a spray

chamber scrubber (see Fig 4), water droplets

are continuously sprayed into the air stream

where water soluble contaminants are continuously

sprayed into the air stream where water

soluble contaminants are absorbed by the

droplets. The fan pulls the air through

the spray, a mist eliminator, and then release

it to atmosphere free of water soluble contaminants.

The mist eliminator traps water droplets

and mists carried by the momentum of the

air and prevents it from being released

through the stack.

Fig

4:- Sprey chamber scrubber.

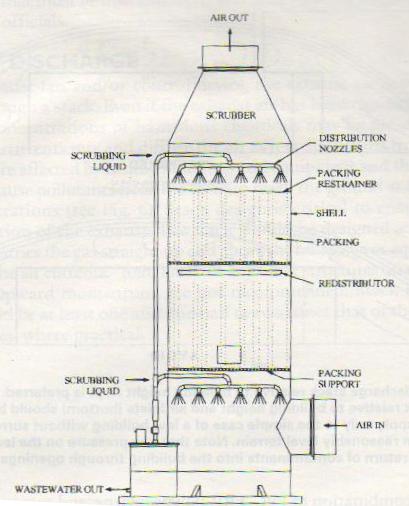

Komalís

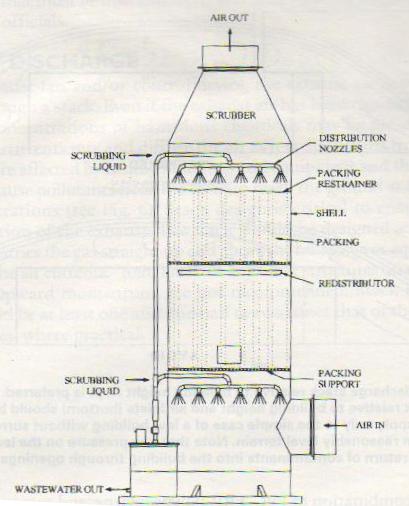

Packed bed scrubbers (see Fig 5) are the

most efficient of the commonly used wet

collectors. They are similar to spray chamber

scrubbers but are filled with a packing

material that increases gas-liquid contact.

The air stream enters the chamber from the

bottom and the scrubbing liquid (typically

water) is sprayed onto the packing material

from the top. The scrubbing liquid trickles

downward through the packing where the air

stream passes upward through packing. The

large surface area for gas-liquid contact

makes Komalís packed bed scrubbers highly

efficient for both water soluble gas and

mist removal.

Fig

5:- Packed bed scrubber

When you choose Komal,

you can count on a fully warranted, corrosion

resistant air pollution control system,

that solves your need in a creative manner

that maximizes value at a reasonable cost,

and when your problems are solved, our relationship

has just begun. Fans, fume scrubbers, Mist

Eliminators, Hoods, Ductworks and custom

fabrications are carefully specified, manufactured

with PVC, Polypropylene, FRP and FRP composites

and installed so that you can operate efficiently.

For the equipments, we use the best type

of input materials, so that the exhaust

systems are the very best in terms of value,

durability, reliability and quality. In

the metal finishing industry, wet collectors

(also called wet scrubbers) are the most

suitable pollution control devices for removing

acid/alkali pollutants. Simplest scrubber

is the spray chamber scrubber. Please see

illustrations.

|