|

|

|

|

|

|

|

Komal Chemiequip Pvt. Ltd.

|

|

Original Manufacturers & Global Suppliers of Automatic Plants, Equipments & Consumables for Electroplating | Surface Finishing & Effluent Treatment |

|

|

|

|

|

|

|

|

|

|

|

|

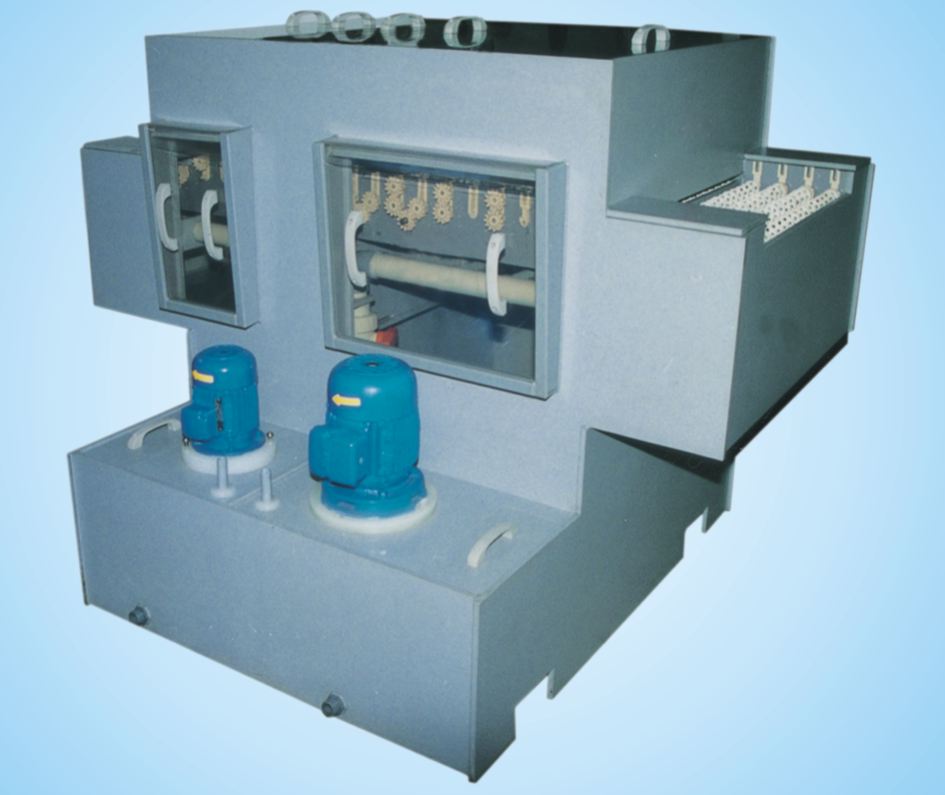

ROLLER

TINNING AND ETCHING MACHINE

|

|

|

|

|

ROLLER

TINNING MACHINE:

This Tin/Solder Coating Machine is used for coating the Tin or Solder

(or other metal) on Printed Circuit Board. This improves the solderability and protects the PCBs. The clean

drilled PCB upto 310mm width (also available

450 and 600mm) is passed between the coating rollers, rotating at 0.25 r.p.m. The bottom roller transfers tin or solder

alloy for the PCB, and the top roller applies uniform pressure for

uniform coating. The metal bath is of 7 kgs. capacity, duly insulated and fitted with an

electronic temperature controller, 2x0.75 KW heater, 12V DC high

torque, variable speed motor, with AC lower drive housing AC input

230V, 50cycles. The unit is housed in stainless steel body or coated

with special epoxy coating to ensure durability. Also fitted with

Mains, on-off switch, Heaters on - off, Controls & Indicators are

housed in a separate or built-in control console.

|

|

|

|

|

|

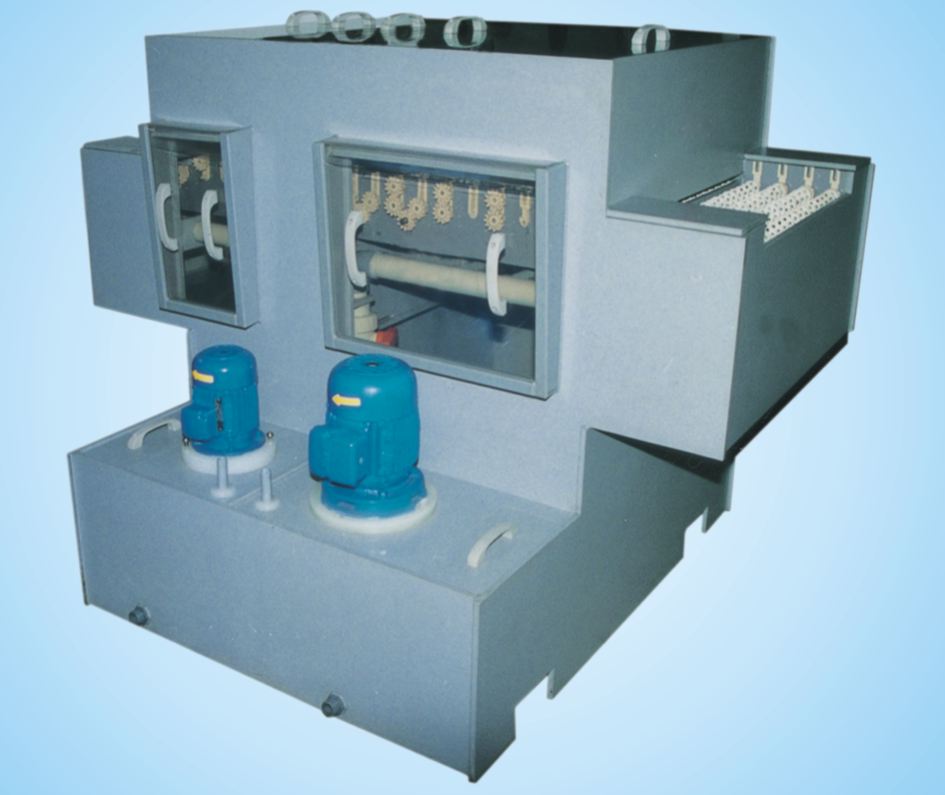

ETCHING

MACHINE:

Vertical Etching Machines are designed for modern etching of Line and Halfone plates (copper or zinc), aluminium metal lables,

also etching of printed circuits boards by conventional process. These

machines are made of acid resisting PVC such as nitric, chromic, cupric

and ferric chloride. The thickness of PVC sheet is 5 mm, and mounted

upon an iron base provided with anti-rust paint. The acid tank is

fitted with a plastic tube for draining out acid. There is also a fume

exhaust to let out the acid fumes to conform to the Factories Act

Regulations. Plastic cover for motor is provided to safe guard the

motor from acid.

|

|

|

|

|

|

|

|

Model

|

KEM 1

|

KEM 2

|

|

Max. plate size

|

4 plates of 30 x 38 cm

|

4 plates of 40 x 50 cm

|

|

Etching time

|

4 minutes

|

4 minutes

|

|

Bath capacity

|

30 litres

|

60 litres

|

|

Floor space

|

55 x 55 cm

|

80 x 80 cm

|

|

Overall height

|

100 cm (40")

|

140 cm (56")

|

|

Motor

|

1/4 H.P. 1/220/50 A.C.

|

1/4 H.P. 1/220/50 A.C.

|

|

Rinsing ratio

|

acid : water 1 : 5

|

acid : water 1 : 5

|

|

|

ALSO AVAILABLE:

Bigger unit of 120 lit. capacity,

Racks for mounting PCBs & Horizontal Heater with Temperature

Controller.

CONVEYORISED ETCHING

MACHINE :

This machine is for PCB etching ranging from 6 x 6 cm

to 60 cm. X any length in PVC Body with PVC Tank, Recirculation

Pump, DC Geared Motor for variable speed of conveyer,

Titanium Cooling Coil, Heater, Sprays in both Etching

and Rinsing Chambers, Loading Zone, Unloading Zone, Conveyor

Rods, PP Discs, PP Gears, Ti. Shaft etc, Solution sump

capacity 100 ltrs. with motorised chemical pumps for etching and spray zone.

Also available Conveyorised Developer Machine, Ink-Stripping

Machine, V - Grooving Machine, Auto Stacker etc.

|

|

|

All

details listed herein are for general guidance, subject to change and hence

not a commitment.

|